GENERAL FEATURES

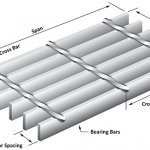

Panorama Bridge Grating is constructed of varying sizes of load bar bearing bars at various pitches, with square twisted cross roads forge welded to the upper edges. The simultaneous application of high electrical current and hydraulic pressure in the welding process produces a gate of considerable rigidity and strength capable of supporting load and giving maximum resistance to twisting, distortion and wear.

MATERIALS AND STANDARDS

Panorama Bridge is constructed of high quality materials that confirms to the following standards

STEEL : BS-EN 10025,grade, S275 JR, ASTM

A36 and JIS G3101 SS400

GALVANISING : BS 729, ASTM A 123 and JIS H8641

AVAILABILITY

Panorama Bridge is available in standard nominal panel size of 1.0 meter wide X 6.0 meter long ( 3’ 3’’ X 20.0’) (nominal). Other sizes are available upon request. The treatment of Panorama Bridge is available in three forms of UNTRETED, PLAIN or GALVANIZED.

MANUFACTURING STANDARDS

Panorama Bridge is designed and manufactured in accordance with relevant International Standards. The safe load and deflection calculation as contained in tables on page 7 , 9 and 11 comply with Australian Standard 1250-1980 while the manufacturer meets the requirements of BSEN 10025 and the Metal Bar Grating division of the National Association of Architectural Metal Manufacturers (NAAMM).

GENERAL FEATURES

Listed below are the various general features of Panorama Bridge Steel Grating:

1, STANDARD AND LIGHTWEIGHT

Panorama Bridge Grating is constructed of load bearing bars and cross roads that are most effectively arranged together to form a grating.

They are jointed securely at their intersections with a specially designed projection welder, thus the grating panels become light but rugged in construction.

2, ECONOMICAL

Panorama Bridge Grating is available in various combinations of load bar sizes and cross rod load bar pitch o suit the application and load conditions. The grating is also zinc coated by the hot-dip process or painted to fit the atmospheric conditions, resulting in enhance durability and greater economy.

3, NON-SLIP AND SAFE

The load bearing bars and cross rods on Panorama Bridge Grating panel are orthogonally arrayed in the forms of grate, affording non-slip protection in every direction to give complete safety.

4, SUPERB IN VENTILATION AND LIGHT ADMISSION

The Panorama Grating panel has a good percentage of open area and is suited for use in places requiring ventilation and nature illumination.

5, SIMPLE FIELD INSTALLATION WORK

Our installation method is simple and easy. As the grating is easily cut according to any required specifications, the field work is made easy and quick.

6, ENVIRONMENTALLY ATTRACTIVE

Geometric lattice patterns formed by the load bearing bars and cross rods make it environmentally attractive.

APPLICATION

Steel grating have been traditionally specified for use as industrial floorings but this use is not limited there. Other applications include platforms, elevated floors, walkway, drain or trench covers, stairs treads, ladder treads, concrete armouring and ventilating screens.

Panorama Bridge Grating is available in numerous combinations of load bar depth and thickness, load bar pitch and cross rod pitch to suit any range of applications. The various types of standard gratings are shown in the following pages of this brochure.

TECHNICAL DATA

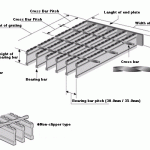

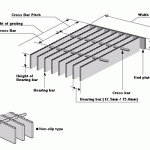

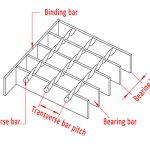

Load Bearing bars

The load bearing bars of varying sizes (h+20mm to 65mm and t=3mm or 5mm) are arranged perpendicularly with equal spacings and parallel to one another to greater load. The load bar pitch (LP) is available in three standard setting of 30mm , 40mm, or 60mm.

Cross rods

The cross rods are forge welded perpendicularly with equal spacing to the lad bearing bras. Twisted square bars (6mm x 6mm) are used for cross rods to maintain the structural precision and perform a non slip function. The cross rod pitch (CP) is available in two setting of 50mmm or 100mm.

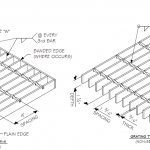

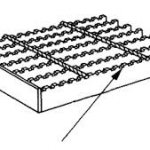

Plain or serrated

The standard type of Panorama Bridge Grating is supplied with plain load bearing bars and 6mm square twisted rods. Panorama Bridge Grating can be supplied with serrated load bearing bars which is formed with a series of notches along the upper edges of the load bars. Serrated Panorama Bridge Grating has improved non-slip characteristics for oily and greasy conditions which is suited particularly for offshore oil and gas industry applications.

Note: When serrated Panorama Bridge Grating is nominated , serrated conversion factors shown below the safe load tables should be used in determining load bearing and spanning capacity.

Cut Outs

Panorama Bridge Grating can be made to any shape and dimensions required. Made to order sizes can be straight and /or surved shaped and can be banded with toe plates or banding bars to suit customers’s requirments.

Note : for non standard load pitch (LP) and cross rod pitch (CP) availability may be dependent upon quantity required. Our sales office should be contacted for further information.

U = Safe superimposed uniformly distributed load kilopascals.

D = Deflection in millimetres.

Mass Calculated with grating in an untreated condition.

Loads calculated in accordance with an allowable bending stress 171.6MPa(0.66Fy)

Load bars are assumed simply supported and unserrated steel with Fy = 260MPa.

Series 1 CS Grating stands for 30mm load bar pitch and is the most commonly specified and used throughout all industries. Series 1 grating has the strongest resistance to loading impact and is used widely in Power Plants refineries, petrochemical plants, trafficable drain grates and offshore oil & gas platforms.

Table of Loads And Defections Series 1

| Type | Cross Rod pitch (mm) | Mass(Kg/m²) | Load Bar Size (mm) | 150 | 300 | 450 | 600 | 750 | 900 | 1050 | 1200 | 1500 | 1800 | 2100 | 2400 | 2700 | 3000 | 3300 | 3600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CSA203 | 100 | 18.8 | 20 * 3 | U402D0.2 | U100D0.8 | U45D1.81 | U25D3.22 | U16D5.03 | U11D7.24 | U8D9.85 | U6D12.87 | U4D20.11 | U3D28.96 | U2D39.41 | |||||

| CSB203 | 50 | 21.7 | 20 *3 | U402D0.2 | U100D0.8 | U45D1.81 | U25D3.22 | U16D5.03 | U11D7.24 | U8D9.85 | U6D12.87 | U4D20.11 | U3D28.96 | U2D39.41 | |||||

| CSA205 | 100 | 29.5 | 20 * 5 | U671D0.2 | U167D0.8 | U74D1.81 | U42D3.22 | U27D5.03 | U18D7.24 | U13D8.85 | U10D12.87 | U6D20.11 | U4D28.96 | U3D39.41 | |||||

| CSB205 | 50 | 32.3 | 20 * 5 | U671D0.2 | U167D0.8 | U74D1.81 | U42D3.22 | U27D5.03 | U18D7.24 | U13D8.85 | U10D12.87 | U6D20.11 | U4D28.96 | U3D39.41 | |||||

| CSA253 | 100 | 22.8 | 25 *3 | U629D0.16 | U157D0.64 | U70D1.45 | U39D2.57 | U25D4.02 | U17D5.8 | U13D7.88 | U10D10.3 | U6D16.09 | U4D23.17 | U3D31.53 | U2D41.18 | ||||

| CSB253 | 50 | 25.7 | 25 * 3 | U629D0.16 | U157D0.64 | U70D1.45 | U39D2.57 | U25D4.02 | U17D5.8 | U13D7.88 | U10D10.3 | U6D16.09 | U4D23.17 | U3D31.53 | U2D41.18 | ||||

| CSA254.5 | 100 | 32.9 | 25 * 4.5 | U953D0.16 | U238D0.64 | U106D1.45 | U59D2.57 | U38D4.02 | U26D5.79 | U19D7.88 | U15D10.3 | U9D16.09 | U6D23.17 | U5D31.53 | U3D41.18 | ||||

| CSB254.5 | 50 | 35.8 | 25 * 4.5 | U953D0.16 | U238D0.64 | U106D1.45 | U59D2.57 | U38D4.02 | U26D5.79 | U19D7.88 | U15D10.3 | U9D16.09 | U6D23.17 | U5D31.53 | U3D41.18 | ||||

| CSA255 | 100 | 36.2 | 25 * 5 | U1048D0.16 | U262D0.64 | U115D1.45 | U65D2.57 | U42D4.02 | U29D5.79 | U21D7.88 | U16D10.3 | U10D16.09 | U7D23.17 | U5D31.53 | U4D41.18 | ||||

| CSB255 | 50 | 39 | 25 * 5 | U1048D0.16 | U262D0.64 | U115D1.45 | U65D2.57 | U42D4.02 | U29D5.79 | U21D7.88 | U16D10.3 | U10D16.09 | U7D23.17 | U5D31.53 | U4D41.18 | ||||

| CSA323 | 100 | 28.4 | 32 * 3 | U1031D0.13 | U257D0.5 | U114D1.13 | U64D2.01 | U41D3.41 | U28D4.52 | U21D6.16 | U16D8.04 | U10D12.57 | U7D18.1 | U5D24.63 | U4D32.18 | U3D40.72 | |||

| CSB323 | 50 | 31.3 | 32 * 3 | U1031D0.13 | U257D0.5 | U114D1.13 | U64D2.01 | U41D3.41 | U28D4.52 | U21D6.16 | U16D8.04 | U10D12.57 | U7D18.1 | U5D24.63 | U4D32.18 | U3D40.72 | |||

| CSA324.5 | 100 | 41.3 | 32 * 4.5 | U1562D0.13 | U390D0.5 | U173D1.13 | U97D2.01 | U62D3.14 | U48D4.52 | U31D6.16 | U24D8.04 | U15D12.57 | U10D18.1 | U8D24.63 | U6D32.18 | U4D40.72 | |||

| CSB324.5 | 50 | 44.2 | 32 * 4.5 | U1562D0.13 | U390D0.5 | U173D1.13 | U97D2.01 | U62D3.14 | U48D4.52 | U31D6.16 | U24D8.04 | U15D12.57 | U10D18.1 | U8D24.63 | U6D32.18 | U4D40.72 | |||

| CSA325 | 100 | 45.5 | 32 * 5 | U1718D0.13 | U429D0.5 | U190D1.13 | U107D2.01 | U68D3.14 | U47D4.52 | U35D6.16 | U26D8.04 | U17D12.57 | U11D18.1 | U8D24.63 | U6D32.18 | U5D40.72 | |||

| CSB325 | 50 | 48.4 | 32 * 5 | U1718D0.13 | U429D0.5 | U190D1.13 | U107D2.01 | U68D3.14 | U47D4.52 | U35D6.16 | U26D8.04 | U17D12.57 | U11D18.1 | U8D24.63 | U6D32.18 | U5D40.72 | |||

| CSA403 | 100 | 34.9 | 40 * 3 | U1610D0.1 | U402D0.4 | U179D.09 | U100D1.61 | U64D2.51 | U44D3.62 | U33D4.93 | U25D6.44 | U16D10.05 | U11D14.48 | U8D19.71 | U6D25.74 | U5D32.58 | U4D40.22 | ||

| CSB403 | 50 | 37.7 | 40 * 3 | U1610D0.1 | U402D0.4 | U179D.09 | U100D1.61 | U64D2.51 | U44D3.62 | U33D4.93 | U25D6.44 | U16D10.05 | U11D14.48 | U8D19.71 | U6D25.74 | U5D32.58 | U4D40.22 | ||

| CSA355 | 100 | 49.6 | 35 * 5 | U2076D0.11 | U519D0.46 | U230D1.03 | U129D1.84 | U83D2.87 | U57D4.14 | U42D5.63 | U32D7.35 | U20D11.49 | U14D16.55 | U10D22.52 | U8D29.42 | U6D37.23 | |||

| CSB355 | 50 | 52.5 | 35 * 5 | U2076D0.11 | U519D0.46 | U230D1.03 | U129D1.84 | U83D2.87 | U57D4.14 | U42D5.63 | U32D7.35 | U20D11.49 | U14D16.55 | U10D22.52 | U8D29.42 | U6D37.23 | |||

| CSA384.5 | 100 | 48.5 | 38 * 4.5 | U2202D0.11 | U550D0.42 | U244D0.95 | U137D1.69 | U88D2.65 | U61D3.81 | U44D5.19 | U34D6.77 | U22D10.58 | U15D15.24 | U11D20.74 | U8D27.09 | U6D34.29 | |||

| CSB384.5 | 50 | 51.4 | 38 * 4.5 | U2202D0.11 | U550D0.42 | U244D0.95 | U137D1.69 | U88D2.65 | U61D3.81 | U44D5.19 | U34D6.77 | U22D10.58 | U15D15.24 | U11D20.74 | U8D27.09 | U6D34.29 | |||

| CSA385 | 100 | 53.6 | 38 * 5 | U2447D0.11 | U611D0.42 | U271D0.95 | U152D1.69 | U97D2.65 | U67D3.81 | U49D5.19 | U38D6.77 | U24D10.58 | U16D15.24 | U12D20.74 | U9D27.09 | U7D34.29 | U6D42.34 | ||

| CSB385 | 50 | 56.5 | 38 * 5 | U2447D0.11 | U611D0.42 | U271D0.95 | U152D1.69 | U97D2.65 | U67D3.81 | U49D5.19 | U38D6.77 | U24D10.58 | U16D15.24 | U12D20.74 | U9D27.09 | U7D34.29 | U6D42.34 | ||

| CSA405 | 100 | 56.2 | 40 * 5 | U2684D0.1 | U671D0.4 | U298D0.9 | U167D1.61 | U107D2.51 | U74D3.62 | U54D4.93 | U41D6.44 | U26D10.05 | U18D14.48 | U13D19.71 | U10D25.74 | U8D32.58 | U6D40.22 | ||

| CSB405 | 50 | 59 | 40 * 5 | U2684D0.1 | U671D0.4 | U298D0.9 | U167D1.61 | U107D2.51 | U74D3.62 | U54D4.93 | U41D6.44 | U26D10.05 | U18D14.48 | U13D19.71 | U10D25.74 | U8D32.58 | U6D40.22 | ||

| CSA455 | 100 | 62.9 | 45 * 5 | U3397D0.09 | U849D0.34 | U377D0.8 | U212D1.43 | U135D2.23 | U94D3.22 | U69D4.38 | U52D5.72 | U33D8.94 | U23D12.87 | U17D17.52 | U13D22.88 | U10D28.96 | U8D35.75 | U6D43.26 | |

| CSB455 | 50 | 65.7 | 45 * 5 | U3397D0.09 | U849D0.34 | U377D0.8 | U212D1.43 | U135D2.23 | U94D3.22 | U69D4.38 | U52D5.72 | U33D8.94 | U23D12.87 | U17D17.52 | U13D22.88 | U10D28.96 | U8D35.75 | U6D43.26 | |

| CSA505 | 100 | 69.6 | 50 * 5 | U4194D0.08 | U1048D0.32 | U465D0.72 | U261D1.29 | U167D2.01 | U116D2.9 | U85D3.94 | U65D5.15 | U41D8.04 | U28D11.58 | U21D15.77 | U16D20.59 | U12D26.06 | U10D32.18 | U8D38.93 | U7D46.33 |

| CSB505 | 50 | 72.4 | 50 * 5 | U4194D0.08 | U1048D0.32 | U465D0.72 | U261D1.29 | U167D2.01 | U116D2.9 | U85D3.94 | U65D5.15 | U41D8.04 | U28D11.58 | U21D15.77 | U16D20.59 | U12D26.06 | U10D32.18 | U8D38.93 | U7D46.33 |

| CSA655 | 100 | 89.6 | 65 * 5 | U7088D0.06 | U1771D0.25 | U787D0.56 | U442D0.99 | U283D1.55 | U196D2.23 | U144D3.03 | U110D3.96 | U70D6.19 | U48D8.91 | U35D12.13 | U27D15.84 | U21D20.05 | U17D24.75 | U14D29.95 | U11D35.64 |

| CSB655 | 50 | 92.4 | 65 * 5 | U7088D0.06 | U1771D0.25 | U787D0.56 | U442D0.99 | U283D1.55 | U196D2.23 | U144D3.03 | U110D3.96 | U70D6.19 | U48D8.91 | U35D12.13 | U27D15.84 | U21D20.05 | U17D24.75 | U14D29.95 | U11D35.64 |

Normal Dimension of Bars Series 1

| NO. of bars | 5mm load bars |

|---|---|

| 4 | 95 |

| 5 | 125 |

| 6 | 155 |

| 7 | 185 |

| 8 | 215 |

| 9 | 245 |

| 10 | 275 |

| 11 | 305 |

| 12 | 335 |

| 13 | 365 |

| 14 | 395 |

| 15 | 425 |

| 16 | 455 |

| 17 | 485 |

| 18 | 515 |

| 19 | 545 |

| 20 | 575 |

| 21 | 605 |

| 22 | 635 |

| 23 | 665 |

| 24 | 695 |

| 25 | 725 |

| 26 | 755 |

| 27 | 785 |

| 28 | 815 |

| 29 | 845 |

| 30 | 875 |

| 31 | 905 |

| 32 | 935 |

| 33 | 965 |

| 34 | 995 |

Serrated Conversion Factors Series 1

| Load bar | Load | Deflection |

|---|---|---|

| 20*3 | ||

| 20*5 | ||

| 25*3 | 0.79 | 1.12 |

| 25*4.5 | 0.79 | 1.12 |

| 25*5 | 0.79 | 1.12 |

| 32*3 | 0.83 | 1.09 |

| 32*4.5 | 0.83 | 1.09 |

| 32*5 | 0.83 | 1.09 |

| 32*4.5 | 0.85 | 1.08 |

| 33*5 | 0.85 | 1.08 |

| 38*5 | 0.86 | 1.07 |

| 40*3 | 0.87 | 1.07 |

| 40*5 | 0.87 | 1.07 |

| 45*5 | 0.88 | 1.07 |

| 50*5 | 0.89 | 1.06 |

| 65*5 | 0.92 | 1.04 |

Series 2 CS Grating with its 40mm load bar pitch is light weight and economical. Its applications are most suited to areas of limited span. Uses include walkways, racks ornamental grills, defecting fenders and loadder treads.

Table of Loads And Defections Series 2

| Type | Cross Rod pitch (mm) | Mass(Kg/m²) | Load Bar Size (mm) | 150 | 300 | 450 | 600 | 750 | 900 | 1050 | 1200 | 1500 | 1800 | 2100 | 2400 | 2700 | 3000 | 3300 | 3600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CSA203 | 100 | 14.6 | 20 * 3 | U305D0.2 | U76D0.8 | U34D1.8 | U19D3.21 | U12D5.02 | U8D7.23 | U6D9..85 | U5D12.87 | U3D20.11 | U2D28.95 | U1D39.41 | |||||

| CSB203 | 50 | 17.4 | 20 *3 | U305D0.2 | U76D0.8 | U34D1.8 | U19D3.21 | U12D5.02 | U8D7.23 | U6D9..85 | U5D12.87 | U3D20.11 | U2D28.95 | U1D39.41 | |||||

| CSA205 | 100 | 22.5 | 20 * 5 | U508D0.2 | U127D0.8 | U56D1.8 | U32D3.21 | U20D5.02 | U14D7.23 | U10D9.85 | U8D12.87 | U5D20.1 | U3D28.96 | U2D39.41 | |||||

| CSB205 | 50 | 25.3 | 20 * 5 | U508D0.2 | U127D0.8 | U56D1.8 | U32D3.21 | U20D5.02 | U14D7.23 | U10D9.85 | U8D12.87 | U5D20.1 | U3D28.96 | U2D39.41 | |||||

| CSA253 | 100 | 17.5 | 25 *3 | U476D0.16 | U119D0.64 | U53D1.44 | U30D2.57 | U19D4.02 | U13D5.79 | U10D7.88 | U7D10.29 | U5D16.08 | U3D23.16 | U2D31.53 | U2D41.18 | ||||

| CSB253 | 50 | 20.4 | 25 * 3 | U476D0.16 | U119D0.64 | U53D1.44 | U30D2.57 | U19D4.02 | U13D5.79 | U10D7.88 | U7D10.29 | U5D16.08 | U3D23.16 | U2D31.53 | U2D41.18 | ||||

| CSA254.5 | 100 | 25.4 | 25 * 4.5 | U715D0.16 | U176D0.64 | U79D1.45 | U44D2.57 | U28D4.02 | U20D5.79 | U14D7.88 | U11D10.3 | U7D16.09 | U5D23.17 | U3D31.53 | U3D41.18 | ||||

| CSB254.5 | 50 | 28.3 | 25 * 4.5 | U715D0.16 | U176D0.64 | U79D1.45 | U44D2.57 | U28D4.02 | U20D5.79 | U14D7.88 | U11D10.3 | U7D16.09 | U5D23.17 | U3D31.53 | U3D41.18 | ||||

| CSA255 | 100 | 27.4 | 25 * 5 | U794D0.16 | U198D0.64 | U88D1.44 | U49D2.57 | U31D4.02 | U22D5.79 | U16D7.88 | U12D10.29 | U8D16.08 | U5D23.16 | U4D31.53 | U3D41.18 | ||||

| CSB255 | 50 | 30.2 | 25 * 5 | U794D0.16 | U198D0.64 | U88D1.44 | U49D2.57 | U31D4.02 | U22D5.79 | U16D7.88 | U12D10.29 | U8D16.08 | U5D23.16 | U4D31.53 | U3D41.18 | ||||

| CSA323 | 100 | 21.7 | 32 * 3 | U781D0.12 | U195D0.5 | U87D1.13 | U49D2.01 | U31D3.14 | U21D4.52 | U16D6.16 | U12D8.04 | U8D12.56 | U5D18.09 | U4D24.63 | U3D32.17 | U2D40.72 | |||

| CSB323 | 50 | 24.5 | 32 * 3 | U781D0.12 | U195D0.5 | U87D1.13 | U49D2.01 | U31D3.14 | U21D4.52 | U16D6.16 | U12D8.04 | U8D12.56 | U5D18.09 | U4D24.63 | U3D32.17 | U2D40.72 | |||

| CSA324.5 | 100 | 31.7 | 32 * 4.5 | U1171D0.13 | U293D0.5 | U130D1.13 | U73D2.01 | U47D3.14 | U32D4.52 | U24D6.15 | U18D8.04 | U11D12.57 | U8D18.1 | U6D24.63 | U4D32.18 | U3D40.72 | |||

| CSB324.5 | 50 | 34.6 | 32 * 4.5 | U1171D0.13 | U293D0.5 | U130D1.13 | U73D2.01 | U47D3.14 | U32D4.52 | U24D6.15 | U18D8.04 | U11D12.57 | U8D18.1 | U6D24.63 | U4D32.18 | U3D40.72 | |||

| CSA325 | 100 | 34.2 | 32 * 5 | U1301D0.12 | U325D0.5 | U144D1.13 | U81D2.01 | U52D3.14 | U36D4.52 | U26D6.15 | U20D8.04 | U13D12.56 | U9D18.09 | U6D24.63 | U5D32.17 | U4D40.72 | |||

| CSB325 | 50 | 37.1 | 32 * 5 | U1301D0.12 | U325D0.5 | U144D1.13 | U81D2.01 | U52D3.14 | U36D4.52 | U26D6.15 | U20D8.04 | U13D12.56 | U9D18.09 | U6D24.63 | U5D32.17 | U4D40.72 | |||

| CSA403 | 100 | 26.4 | 40 * 3 | U1220D0.1 | U305D0.4 | U135D0.9 | U76D1.61 | U49D2.51 | U34D3.62 | U25D4.93 | U19D6.44 | U12D10.05 | U8D14.48 | U6D19.71 | U4D25.74 | U3D32.58 | U3D40.22 | ||

| CSB403 | 50 | 29.2 | 40 * 3 | U1220D0.1 | U305D0.4 | U135D0.9 | U76D1.61 | U49D2.51 | U34D3.62 | U25D4.93 | U19D6.44 | U12D10.05 | U8D14.48 | U6D19.71 | U4D25.74 | U3D32.58 | U3D40.22 | ||

| CSA355 | 100 | 37.9 | 35 * 5 | U1557D0.11 | U389D0.46 | U173D1.03 | U97D1.84 | U62D2.87 | U43D4.14 | U31D5.63 | U24D7.35 | U15D11.49 | U10D16.55 | U8D22.52 | U6D29.42 | U4D37.23 | |||

| CSB355 | 50 | 40.8 | 35 * 5 | U1557D0.11 | U389D0.46 | U173D1.03 | U97D1.84 | U62D2.87 | U43D4.14 | U31D5.63 | U24D7.35 | U15D11.49 | U10D16.55 | U8D22.52 | U6D29.42 | U4D37.23 | |||

| CSA384.5 | 100 | 37.1 | 38 * 4.5 | U1652D0.11 | U413D0.42 | U183D0.95 | U103D1.69 | U66D2.65 | U45D3.81 | U33D5.19 | U25D6.77 | U16D10.58 | U11D15.24 | U8D20.74 | U6D27.09 | U5D34.29 | |||

| CSB384.5 | 50 | 40 | 38 * 4.5 | U1652D0.11 | U413D0.42 | U183D0.95 | U103D1.69 | U66D2.65 | U45D3.81 | U33D5.19 | U25D6.77 | U16D10.58 | U11D15.24 | U8D20.74 | U6D27.09 | U5D34.29 | |||

| CSA385 | 100 | 40.9 | 38 * 5 | U1835D0.11 | U458D0.42 | U204D0.95 | U114D1.69 | U73D2.65 | U51D3.81 | U37D5.19 | U28D6.77 | U18D10.58 | U12D15.24 | U9D20.74 | U7D27.09 | U5D34.29 | U4D42.34 | ||

| CSB385 | 50 | 43.8 | 38 * 5 | U1835D0.11 | U458D0.42 | U204D0.95 | U114D1.69 | U73D2.65 | U51D3.81 | U37D5.19 | U28D6.77 | U18D10.58 | U12D15.24 | U9D20.74 | U7D27.09 | U5D34.29 | U4D42.34 | ||

| CSA405 | 100 | 42.1 | 40 * 5 | U2033D0.1 | U508D0.4 | U226D0.9 | U127D1.61 | U81D2.51 | U56D3.61 | U41D4.93 | U31D6.43 | U20D10.05 | U14D14.47 | U10D19.7 | U8D25.74 | U6D32.57 | U5D40.21 | ||

| CSB405 | 50 | 44.9 | 40 * 5 | U2033D0.1 | U508D0.4 | U226D0.9 | U127D1.61 | U81D2.51 | U56D3.61 | U41D4.93 | U31D6.43 | U20D10.05 | U14D14.47 | U10D19.7 | U8D25.74 | U6D32.57 | U5D40.21 | ||

| CSA455 | 100 | 47 | 45 * 5 | U2574D0.08 | U643D0.34 | U286D0.8 | U160D1.43 | U102D2.23 | U71D3.21 | U52D4.37 | U40D5.72 | U25D8.93 | U17D12.87 | U13D17.51 | U10D22.88 | U7D28.95 | U7D35.75 | U5D43.25 | |

| CSB455 | 50 | 49.8 | 45 * 5 | U2574D0.08 | U643D0.34 | U286D0.8 | U160D1.43 | U102D2.23 | U71D3.21 | U52D4.37 | U40D5.72 | U25D8.93 | U17D12.87 | U13D17.51 | U10D22.88 | U7D28.95 | U7D35.75 | U5D43.25 | |

| CSA505 | 100 | 51.9 | 50 * 5 | U3177D0.08 | U794D0.32 | U353D0.72 | U198D1.28 | U127D2.01 | U88D2.89 | U64D3.94 | U49D5.14 | U31D8.04 | U22D11.58 | U16D15.76 | U12D20.59 | U9D26.06 | U7D32.17 | U6D38.93 | U5D46.33 |

| CSB505 | 50 | 54.7 | 50 * 5 | U3177D0.08 | U794D0.32 | U353D0.72 | U198D1.28 | U127D2.01 | U88D2.89 | U64D3.94 | U49D5.14 | U31D8.04 | U22D11.58 | U16D15.76 | U12D20.59 | U9D26.06 | U7D32.17 | U6D38.93 | U5D46.33 |

| CSA655 | 100 | 66.6 | 65 * 5 | U5370D0.06 | U1342D0.25 | U596D0.56 | U335D0.99 | U214D1.55 | U149D2.23 | U109D3.03 | U83D3.96 | U53D6.19 | U37D8.91 | U27D12.13 | U20D15.84 | U16D20.05 | U13D24.75 | U10D29.95 | U9D35.64 |

| CSB655 | 50 | 69.4 | 65 * 5 | U5370D0.06 | U1342D0.25 | U596D0.56 | U335D0.99 | U214D1.55 | U149D2.23 | U109D3.03 | U83D3.96 | U53D6.19 | U37D8.91 | U27D12.13 | U20D15.84 | U16D20.05 | U13D24.75 | U10D29.95 | U9D35.64 |

Normal Dimension of Bars Series 2

| No. of bars | 5mm Load Bars |

|---|---|

| 4 | 125 |

| 5 | 165 |

| 6 | 205 |

| 7 | 245 |

| 8 | 285 |

| 9 | 325 |

| 10 | 365 |

| 11 | 405 |

| 12 | 445 |

| 13 | 485 |

| 14 | 525 |

| 15 | 565 |

| 16 | 605 |

| 17 | 645 |

| 18 | 685 |

| 19 | 725 |

| 20 | 765 |

| 21 | 805 |

| 22 | 845 |

| 23 | 885 |

| 24 | 925 |

| 25 | 965 |

| 26 | 1005 |

Serrated Conversion Factors Series 2

| Load Bar | Load | Deflection |

|---|---|---|

| 20*3 | ||

| 20*5 | ||

| 25*3 | 0.79 | 1.12 |

| 25*4.5 | 0.79 | 1.12 |

| 25*5 | 0.79 | 1.12 |

| 32*3 | 0.83 | 1.09 |

| 32*4.5 | 0.83 | 1.09 |

| 32*5 | 0.83 | 1.09 |

| 32*4.5 | 0.85 | 1.08 |

| 33*5 | 0.85 | 1.08 |

| 38*5 | 0.86 | 1.07 |

| 40*3 | 0.87 | 1.07 |

| 40*5 | 0.87 | 1.07 |

| 45*5 | 0.88 | 1.07 |

| 50*5 | 0.89 | 1.06 |

| 65*5 | 0.92 | 1.04 |

Series 3 CS Grating with its 60mm pitch has the widest grate square opening (50mm * 60mm). This allows most materials to fall through and thus, is suited to applications whereby surface area cleanliness and avoidance of spillage is priority.

Table of Loads And Defections Series 3

| Type | Cross Rod pitch (mm) | Mass(Kg/m²) | Load Bar Size (mm) | 150 | 300 | 450 | 600 | 750 | 900 | 1050 | 1200 | 1500 | 1800 | 2100 | 2400 | 2700 | 3000 | 3300 | 3600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CSB205 | 50 | 19 | 20*5 | U325D0.2 | U81D0.8 | U36D1.81 | U20D3.21 | U13D5.02 | U9D7.23 | U6D9.85 | U5D12.87 | U3D20.1 | U2D28.95 | U1D39.41 | |||||

| CSB253 | 50 | 15.7 | 25*3 | U305D0.16 | U76D0.64 | U34D1.44 | U19D2.57 | U12D4.02 | U8D5.79 | U6D7.88 | U5D10.29 | U3D20.1 | U2D23.16 | U1D31.53 | U1D41.18 | ||||

| CSB254.5 | 50 | 20.8 | 25*4.5 | U476D0.16 | U119D0.64 | U53D1.45 | U30D2.57 | U19D4.02 | U13D5.79 | U10D7.88 | U7D10.3 | U5D16.09 | U3D23.17 | U2D31.53 | U2D41.18 | ||||

| CSB255 | 50 | 22.3 | 25*5 | U508D0.16 | U127D0.64 | U56D1.44 | U32D2.57 | U20D4.02 | U14D5.79 | U10D7.88 | U8D10.29 | U5D16.08 | U3D23.16 | U2D31.55 | U3D41.18 | ||||

| CSB323 | 50 | 18.5 | 32*3 | U500D0.16 | U125D0.5 | U55D1.13 | U31D2.01 | U20D3.14 | U14D4.52 | U10D6.15 | U8D8.04 | U5D12.56 | U3D18.09 | U2D24.63 | U2D32.17 | U1D40.72 | |||

| CSB324.5 | 50 | 25 | 32*4.5 | U781D0.13 | U195D0.5 | U87D1.13 | U49D2.01 | U31D3.14 | U21D4.52 | U16D6.16 | U12D8.04 | U8D12.57 | U5D18.1 | U4D24.63 | U3D32.18 | U2D40.72 | |||

| CSB325 | 50 | 27 | 32*5 | U833D0.12 | U208D0.5 | U92D1.13 | U52D2.01 | U33D3.14 | U23D4.52 | U17D6.15 | U13D8.04 | U8D12.56 | U6D18.09 | U4D24.63 | U3D32.17 | U2D40.72 | |||

| CSB403 | 50 | 21.7 | 40*3 | U781D0.1 | U195D0.4 | U87D0.9 | U49D1.6 | U31.2.51 | U21D3.62 | U16D4.92 | U12D6.43 | U8D10.05 | U5D14.47 | U4D19.7 | U3D25.74 | U2D32.57 | U2D40.21 | ||

| CSB355 | 50 | 29.1 | 35*5 | U1038D0.11 | U259D0.46 | U115D1.03 | U65D1.84 | U41D2.87 | U29D4.14 | U21D5.63 | U16D7.35 | U10.10.49 | U7D16.55 | U5D22.52 | U4D29.42 | U3D37.23 | |||

| CSB384.5 | 50 | 28.6 | 38*4.5 | U1101D0.11 | U275D0.42 | U122D0.95 | U69D1.69 | U44D2.65 | U30D3.81 | U22D5.19 | U17D735 | U11D10.58 | U7D15.24 | U5D20.74 | U4D27.09 | U3D34.29 | |||

| CSB385 | 50 | 31.1 | 38*5 | U1223D0.11 | U306D0.42 | U136D0.95 | U76D1.69 | U49D2.65 | U34D3.81 | U25D5.19 | U19D6.77 | U12D10.58 | U8D15.24 | U6D20.74 | U4D27.09 | U3D34.29 | U3D42.34 | ||

| CSB405 | 50 | 32.3 | 40*5 | U1301D0.1 | U325D0.4 | U144D0.9 | U81D.16 | U52D2.51 | U36D3.62 | U26D4.92 | U20D6.43 | U13D10.05 | U9D14.47 | U6D19.7 | U5D25.74 | U4D32.57 | U3D40.21 | ||

| CSB455 | 50 | 35.7 | 45*5 | U1647D0.08 | U411D0.35 | U183D0.8 | U103D1.43 | U66D2.23 | U45D3.21 | U33D4.37 | U25D5.72 | U16D8.93 | U11D12.87 | U8D17.51 | U6D22.88 | U5D28.95 | U4D35.75 | U3D43.25 | |

| CSB505 | 50 | 39 | 50*5 | U2033D0.08 | U508D0.32 | U226D0.72 | U127D1.28 | U81D2.01 | U56D2.89 | U41DD3.94 | U31D5.14 | U20D8.04 | U14D11.58 | U10D15.76 | U8D20.59 | U6D26.06 | U5D32.17 | U4D38.93 | |

| CSB655 | 50 | 49 | 65*5 | U3437D0.06 | U859D0.24 | U381D0.55 | U214D0.99 | U137D1.54 | U95D2.22 | U70D3.03 | U53D3.96 | U34D6.18 | U23D8.91 | U17D12.12 | U13D15.84 | U10D20.04 | U8D24.75 | U7D29.94 | U5D35.64 |

Normal Dimension of Bars Series 3

| No. of bars | 5mm load bars |

|---|---|

| 4 | 125 |

| 5 | 165 |

| 6 | 205 |

| 7 | 245 |

| 8 | 285 |

| 9 | 325 |

| 10 | 365 |

| 11 | 405 |

| 12 | 445 |

| 13 | 485 |

| 14 | 525 |

| 15 | 565 |

| 16 | 605 |

| 17 | 645 |

| 18 | 685 |

| 19 | 725 |

| 20 | 765 |

| 21 | 805 |

| 22 | 845 |

| 23 | 885 |

| 24 | 925 |

| 25 | 965 |

| 26 | 1005 |

Serrated Conversion Factors Series 3

| Load bar | load | deflection |

|---|---|---|

| 20*3 | ||

| 20*5 | ||

| 25*3 | 0.79 | 1.12 |

| 25*4.5 | 0.79 | 1.12 |

| 25*5 | 0.79 | 1.12 |

| 32*3 | 0.83 | 1.09 |

| 32*4.5 | 0.83 | 1.09 |

| 32*5 | 0.83 | 1.09 |

| 32*4.5 | 0.85 | 1.08 |

| 33*5 | 0.85 | 1.08 |

| 38*5 | 0.86 | 1.07 |

| 40*3 | 0.87 | 1.07 |

| 40*5 | 0.87 | 1.07 |

| 45*5 | 0.88 | 1.07 |

| 50*5 | 0.89 | 1.06 |

| 65*5 | 0.92 | 1.04 |

IB-TYPE I-BARS

The bearing bar comes in the form of an I-section. This type of grating is used where high strength is required and light weight is dritical.

SI-TYPE I-BARS

The bearing bar comes in the form of an I-section with the top surfaceformed by series of notches. These type of grating is addition to is high strength and light weight capabilities has also its non-slip characteristics.

Stair treads

Stair treads are available in 2 standard types with no nosing or chequer plate nosing. Other type of nosing are available no request.

The stair treads can be made from any of our 3 standard types of load bearing bars arrangement.

How to order Panorama Bridge Grating?

1-Type of grating

Specify type of Grating required by reference to our three main types product .

2-DIMENSIONS

-Nominate number of standard 1.0 x 6.1m/0.9 x 6.1m panels required.

-Nominate whether banding is required.

-For non standard panels, nominate dimensions for length and width of individual panels.

-Where large areas of flooring is to be covered, provide :

–a. Shop drawings of grating floor zone.

–b. Detail drawings of beams, pillars and their joints.

–c. Setting positions of stairs and procedures of stair, raillings piping etc.

–d. Sizes and locations of cutouts, kick plates and nosings.

-For stair treads, selects from our range of standard types and nominate dimensions and quality. Our recommended lengths & widths should be nominated for economical orders.

3-FINISHING

-Nominate the type of finish required I.e. untreated, painted or galvanized.

4-ANCHORING METHODS

-Where fastening clamps units are required, select any of our three types of clamping units available. Clamping units should be provided for the basis of a minimum of 4 units per panel.

GLOSSARY OF TERMS

LOAD BEARING BARS Load carrying bars of uniform section spanning between supports.

CROSS RODS( Transverse bars) Twisted square roads of uniform section forge welded perpendicularly to the load bearing bars to provide lateral restraint.

BAND A bar or section welded to the edges of grating panels and also around notches and penetration.

CUT OUTS An area of grating removed to permit pipes, ducts, structural columns, etc. To pass through, or to clear obstructions.

PANELS A piece of grating finished either in standard 1.0 x 6.1m/0.9 x 6.1m form or cut to size, banded and/or notched as specified by customer.

WIDTH The overall dimensions of grating panel measured parallel with the cross roads.( This dimensions is always referred to as the “width” even through it may exceed the length).

LENGHT The overall dimensions of grating measured parallel with the load bearing bars. (The dimensions is always referred to as the “ Length” even through it may be shorter then the width).

SERRATION A series of notches formed along the upper edges of the load bearing bars to improve the non slip characteristic of gratings.

KICK PLATES (Toeplate) A flat bar projecting above the load bearing bars and welded around the edges of a grating panel.

NOSING A slip resistant member welded to the edges of stair treads or to flooring panels.